Feature

- * The machine is made of cast iron, giving it the mass and rigidity to cut tougher metals such as iron, brass, steel

- * User friendly controls

- * Designed for high precision or rapid prototyping of small, precision parts.

Rigid construction

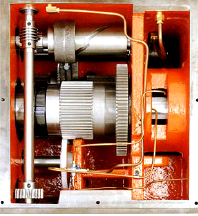

Geared Headstock

The Spindle & gears are made of CR-MO alloy steel which are carburizing & precisely ground, forced lubricating & oil bathed combined in headstock which can be prolonged servicing life

Rugged heavily construction

Rugged heavily ribbed cast iron bed constructed, with hardened and ground Turcite-coated bed and saddle guideways for high accuracy and durability.

Specification

KL-3060 / KL-3080 / KL-30120 / KL-30160 / KL-30200

WORKING CAPACITY |

|||||

| Swing over bed | 770 mm | ||||

| Center height to bed | 385 mm | ||||

| Center height to top cross slide | 250 mm | ||||

| Swing over cross slide | 500 mm | Dis. Between centers | 1600 mm / 2100 mm / 3100 mm / 4100 mm / 5100mm | ||

| Width of bed | 450 mm | ||||

HEADSTOCK |

|||||

| Spindle nose | D1-8 * | A2-11 * | A2-11 | A2-15 | A2-20 |

| Spindle bore | 85 mm (3.34") | 105 mm (4") | 153 mm (6") opt | 230 mm (9") opt | 305 mm (12") opt |

| 3-Jaw scroll chuck (Option) | Ø10" (thr. hole 76 mm) for D1-8 spindle nose only Ø 12" 3-jaw scroll chuck (thr. hole 103 mm) Ø 16" 3-jaw scroll chuck (thr. hole 155 mm) Ø 20" 3-jaw scroll chuck (thr. hole 160 mm) Ø 25" 3-jaw scroll chuck (thr. hole 200 mm) |

||||

| Hydraulic Power chuck (Opt.) | Ø 10" (thr. hole 75 mm) for D1-8 spindle nose Ø 12" (thr. hole 105 mm) for A2-11 spindle nose Ø 15" (thr. hole 117.5 mm) for A2-11 spindle nose, Ø 18" (thr. hole 117.5 mm) for A2-11 spindle nose, Ø 24" (non thr. hole) for A2-15 spindle nose, |

||||

| Bar capacity (Power chuck) | Ø 75 mm for D1-8 of 10" chuck, Ø 91 mm for A1-11 of Ø 12" chuck, Ø 117.5 mm for A1-11 of Ø 15" chuck and Ø 18" chuck |

||||

| Range of spindle speeds | 3 Rang Gears Auto Shifting | ||||

| Spindle speeds range | H: 2000 - 441 rpm M: 440 - 111 rpm L : 110 - 25 rpm |

H: 1500 - 331 rpm M: 330 - 93 rpm L: 92 - 24 rpm |

H: 800 - 176 rpm M: 175 - 59 rpm L: 58 - 12 rpm |

H: 450 - 108 rpm M: 107 - 31rpm L: 30 - 6rpm |

H: 350 - 87rpm M: 86 - 26rpm L: 25 - 5rpm |

| Taper in spindle | MT# 6 | ||||

SADDLE |

|||||

| Longitudinal travel (Z-axis) | 1500 mm / 2000 mm / 3000mm / 4000 mm / 5000mm / 6000 mm | ||||

| Cross-slide travel | 450 mm | ||||

| Size of tool holder | Boring Tool : Ø40 mm, O. D. Tool & Facing Tool: □25 mm | ||||

| Ball screw (Dia x pitch) | X-Axis: Ø25 mm x P 5 mm, Z-Axis: Ø50 mm x P10 mm | ||||

TAILSTOCK |

|||||

| Quill Diameter | Ø 105 mm | ||||

| Quill Travel | 220 mm | ||||

| Quill Taper | MT #5 | ||||

MOTOR |

|||||

| Spindle motor | 20 HP (Std.), 30 HP (option) | ||||

| Z-axis drive motor | 12 Nm (FKM 44.3) | ||||

| X-axis drive motor | 6.3 Nm (FKM 42.3) | ||||

| Coolant pump motor | 1/4 HP - Std, 3/4 HP (Opt.) | ||||

| High Pressure coolant | 1-1/2 HP (Opt. for U drills) 6 bar or 20 bar | ||||

X, Z- AXES FEED |

|||||

| X axis rapid travel | 6 M /min | ||||

| Z axis rapid travel | 8 M /min | ||||

GENERAL |

|||||

| Power Required | 20 KVA | ||||

| Floor space (L x M x H) | 3590/4090/5090/6090/7090 x 1950 x 1820 mm | ||||

| Approx, machine weight | 4500kgs / 5000kgs / 6000kgs / 7000kgs / 8000kgs / 9000 kgs | ||||

KL-2600 Series Spindle with D1-8, Ø85 mm Spindle bore as a standard, KL-3000 and KL-3200 Series Spindle with A2-11, Ø 105 mm Spindle bore as a standard.

- * Specifications are subject to change without prior notice.

- * Actual working travels maybe reduced by Hyd. Turret and Chuck option are fitted.