Feature

- Rigid cast design of machine elements

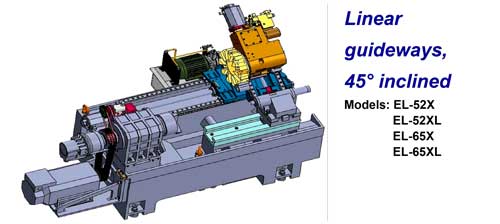

- Linear guideways on X,Z axes for fast machining

- Belt Type Chip Conveyor Standard for efficient chip removal

- Tailstock Standard

- Controller : Siemens 828D, FAGOR 8055i TC, FANUC 0i mate

- Chuck size: 6" Chuck / 6,000 rpm (8" Chuck /4,200 rpm Optional)

- Swing over bed: 450 mm

- 42mm Bar Capacity

- Maximum turning length: 300 mm

- Spindle motor: 7.5/11 kw

Rigid construction

A solid one piece casting is made from close grain Meehanite Cast Iron. The ribbing locations and wall thickness are placed in strategic locations determined by computer finite analysis. This design assures consistent accuracy's and excellent finishes. The Saddle has a 45° degree incline, Designed for easier directing chips and coolant in to the chip conveyor

Specification

EL-42 / EL-52

| EL-42 | EL-52 | |

| Machining Capacity | ||

| Swing Over Bed | Ø450 mm | |

| Swing Over Saddle | Ø280 mm | |

| Max. Turning Length | 300 mm | |

| Max. Turning Diameter | Ø240 | |

| Spindle | ||

| Hyd. Chuck Diameter | 6" Inch | 8" Inch |

| Max. Bar Diameter | Ø42mm | Ø52mm |

| Spindle Nose | A2-5 type | A2-6 type |

| Spindle Bearing Dia. | 90mm | 100mm |

| Spindle Motor 100% / 50% | 7.5 / 11KW | |

| Spindle Speed | 6000rpm | 4500rpm |

| Turret | ||

| Turret Type | Hydraulic / Servo (Opt.) type | |

| Tool Number | 10 Station | |

| Tool Shank (O.D) | □20 | |

| Tool Holder Bore Dia. (I.D) | Ø32 mm | |

| Index time next tool | 0.3sec | |

| Travels | ||

| X-axis Travel | 125 + 20 mm | |

| Z- Axis Travel | 300 mm | |

| Feed | ||

| Rapid Traverse Rate X-Axis | 24 m/min | |

| Rapid Traverse Rate Z-axis | 30 m/min | |

| Maximum Cutting Feedrate | 6 m/min | |

| Accuracies | ||

| Positioning | ±0.003 mm (± .0002") Mm | |

| Repeatability | ± 0.002 mm (± .0001") Mm | |

| Turret | ± 2 arc sec | |

| Motor | ||

| Servo motor in X / Z-axis | 1.4 KW | |

| Hydraulic motor | 2 HP | |

| Coolant pump | 3/4HP | |

| Tailstock | ||

| Quilt Diameter | Ø70 mm | |

| Tailstock quill taper | No.4 MT type | |

| Tailstock travel | 200 mm | |

| Quill travel | 80 mm | |

| control type | Manual | |

| Overview | ||

| X- Z Axis Slideway | Linear Guide Ways type | |

| Connected Load Power Consumption | 20 KVA | |

| Coolant Tank Capacity | 120 liter | |

| Floor Space | 285*145 cm | |

| Machine Weight | 3300 kg | |